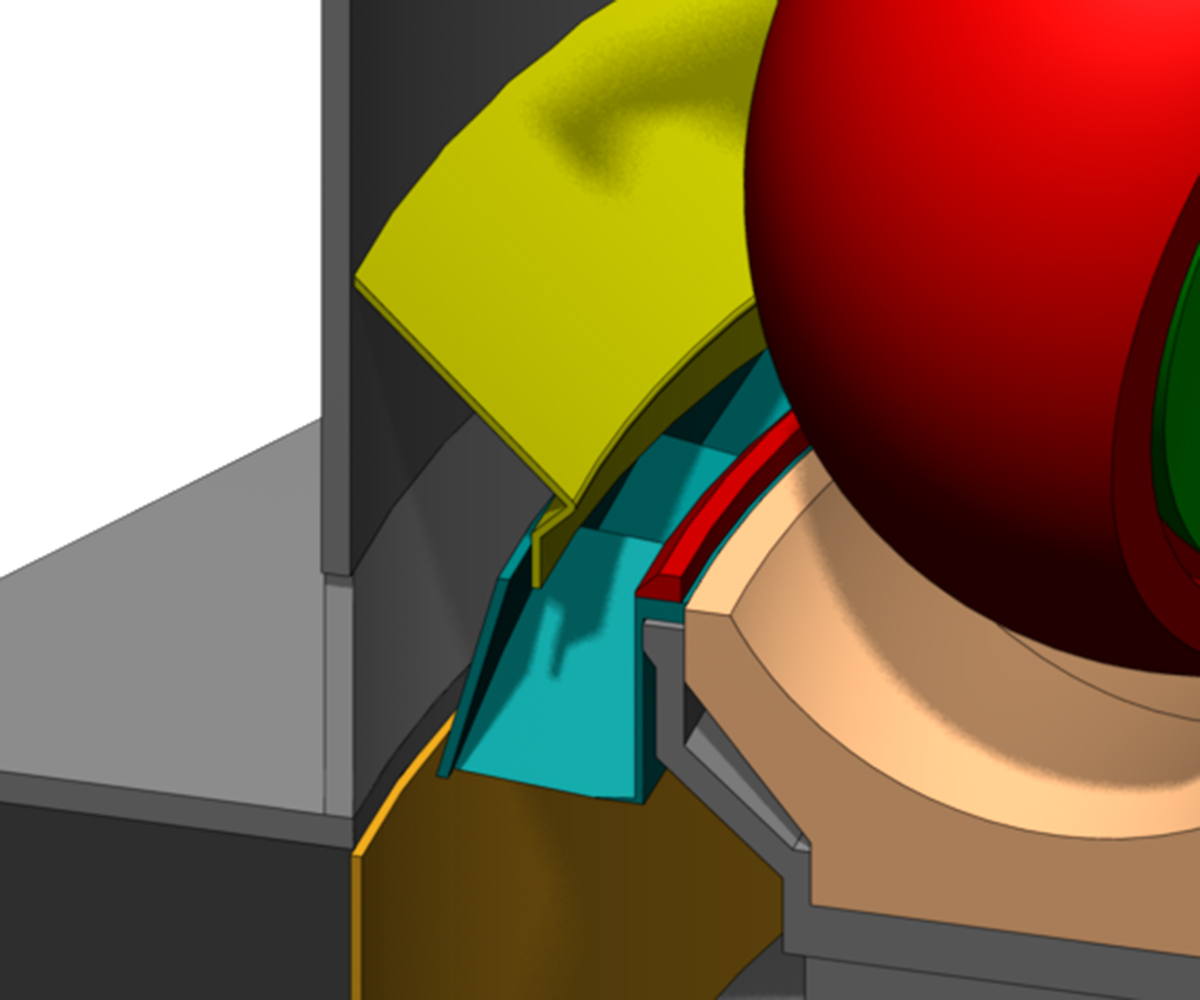

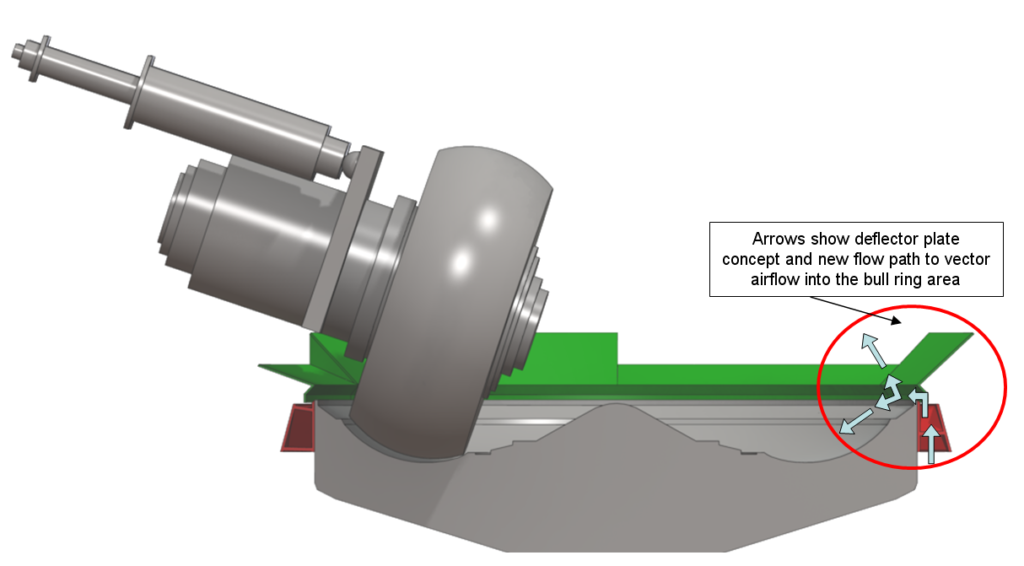

Pulverizer Rotating Throat & Deflector Kits

Are you having excessive coal/pyrite rejects? Are you experiencing mill rumbling because coal particles are not exiting the pulverizer as the should?

-

Maintain an acceptable velocity to keep coal particles in suspension and prevent coal spillage

-

Improve primary air controllability

-

Improve airflow vectoring for better grinding and coal fineness

An optimum pulverizer throat configuration is a big deal. The pulverizer throat area and configuration must be right to minimize coal rejects at the optimum air/fuel ratio; must help turn down to a minimum load without “rumble”; and must be configured to not have quiescent zones that contribute to mill fires. The throat areas must be compatible with the fuel lines and burner nozzle areas so that optimum velocities.

Observable characteristics of good pulverizer performance include minimum coal rejects and no rumbling/skidding. Minimum coal rejects means that your primary airflow, grinding zone and throat areas are compatible and are operating correctly. Maintaining this level of performance is important since too many rejects can pose a fire risk. Rumbling or skidding may not pose a direct performance penalty, but it can affect the long term reliability of the pulverizer components. Lower maintenance costs is an indirect result of optimum pulverizer performance.

Benefits:

- Reduced or eliminated coal rejects, improved vectoring for improved grinding and improved primary airflow controllability.

- Increased pulverizer & furnace residence time.

- Improved coal fineness.

- Capability to reduce air/fuel ratios.

- Reduced FEGT’s with improved combustion lower in the furnace.

- Reduced available “free” oxygen in the high temperature flame core.

- Excessive amounts of primary airflow tend to force ignition points away from the burner as a result of higher burner nozzle velocities, thus allowing infusion of oxygen “rich” air into the flame core and increasing NOx exponentially.

- Reduce pulverizer vibration & rumbling.

- Deflector sets an open area to maintain an acceptable velocity to keep coal particles in suspension and prevent coal spillage.