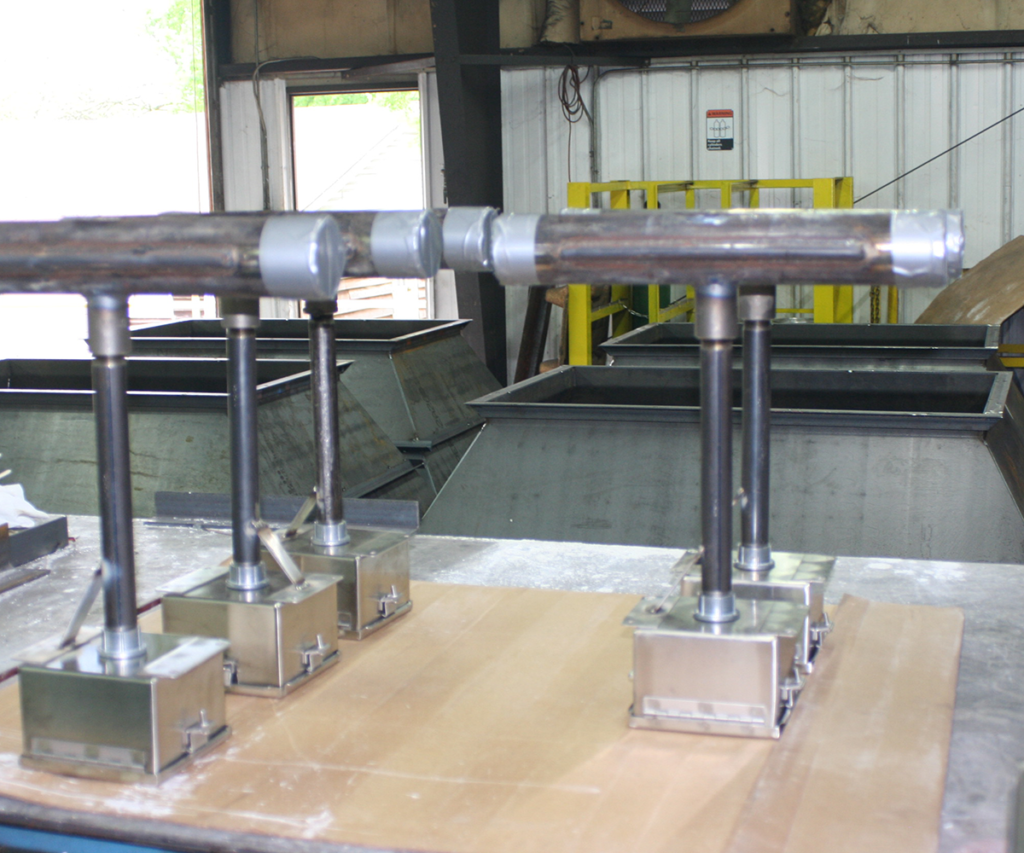

Waterwall Chordal Thermocouples

Are you having boiler tube scaling issues or tube failures occurring? Are your boiler’s waterwalls free from obstruction to allow for optimum circulation? Consider installing chordal thermocouples to monitor the tube temperatures.

Waterwall tube metal temperatures are highest on the fire side of the tube. Usually, on a clean tube, the mean wall temperature is less than 75°F above the saturation temperature. Supercritical boiler furnace wall tubes are usually within similar temperature differences of about 50-75°F between the fluid temperature and the “crown” of the tube on the fire side. However, if circulation is obstructed or more commonly if the water side of the tubes accumulate deposits, the metal temperature can climb to the point of metal overheating.

Chordal thermocouples are a useful tool for predicting waterwall metal temperature distress. The readings from the mean wall temperature of a chordal thermocouple should be recorded weekly, after installation. If a previous problem of water-side deposits caused overheating to the extent that acid cleaning of the boiler was required, then the use of chordal thermocouples are useful tools to record temperatures on a weekly basis. The chordal thermocouple readings are directly related to heat flow through the tube wall. Therefore, the recording of temperatures should always be at the same high load, with the same burners in operation. Recording the mean wall temperature will provide a trend of water-side deposits. It only takes a thin coating of water-side deposits to increase the temperature of the tube metal. Iron oxide deposits have a heat transfer coefficient of about 1/70th of steel. Mineral constituents have even lower heat transfer coefficients.

If the tube metal temperature of a chordal thermocouple continues to gradually climb, then an adjacent tube sample should be removed for internal deposit analysis. This is one way to maximize boiler reliability and prevent surprise waterwall failures. STORM® can design and manufacture these chordal thermocouple tube sections to monitor the mean wall temperature of waterwalls.

Overheating Tube Metal Temperatures by 50°F can Reduce Tube Life by 86.3 Years!!!

Common causes of boiler tube failures:

- Water-plugging of superheater tubes on startup

- Stratified furnace gases with high temperature lanes that overheat specific tubes

- Water-side deposits become more of an issue with cycling due to the shaking up of the pre-boiler cycle during startups and shutdowns.