Fan Boosted Overfire Air Systems

Is your plant challenged by NOx regulations and improvements?

-

Most economical system for the greatest NOx reduction

-

40%-60% NOx reduction (depending on configuration)

-

Approx. 90% of the components can be installed with the unit on-line

STORM® has recommended a fan boosted overfire fan concept for many years and with the stringent NOx emission limits, it is now even more important. Units without fan-boosted overfire air (OFA) systems are not capable of achieving the desired NOx levels without compromising unit deregulations. Many utilities currently struggle with NOx regulations, and improvements must be made.

It has been our experience that anyone can achieve low NOx. However, unit reliability, efficiency, and performance are affected and must be addressed. These include high levels of unburned carbon (LOI levels), high opacity levels, capacity reduction, slagging, forced outages, high spray flows, burner fires, etc.

A fan-boosted OFA system will provide improved mixing and create proper staging for optimum performance and NOx reductions. Testing results have also shown that existing (non-boosted or improper nozzle design) OFA systems are ineffective. The air “oozes” along the sidewalls and fails to provide adequate mixing. A typical Storm fan-boosted over-fire air system will reduce NOx by 40%-60% while maintaining or improving LOI.

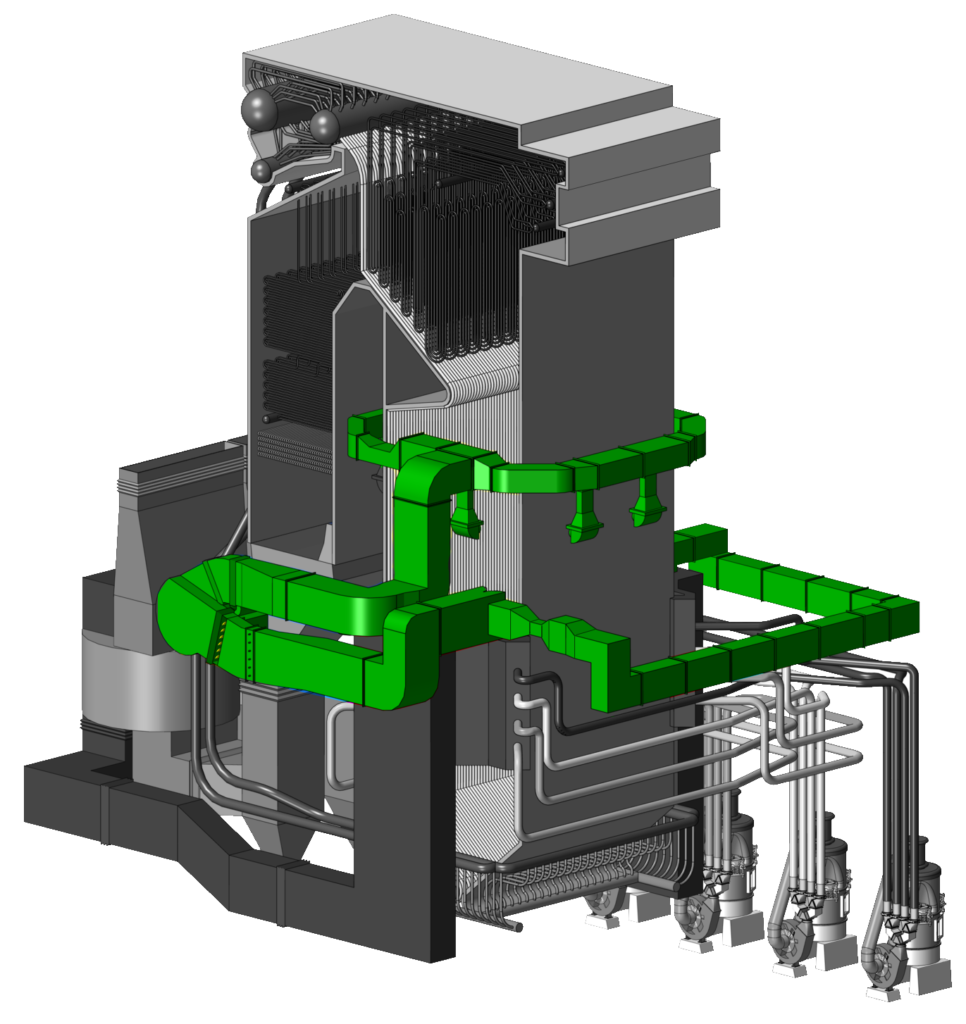

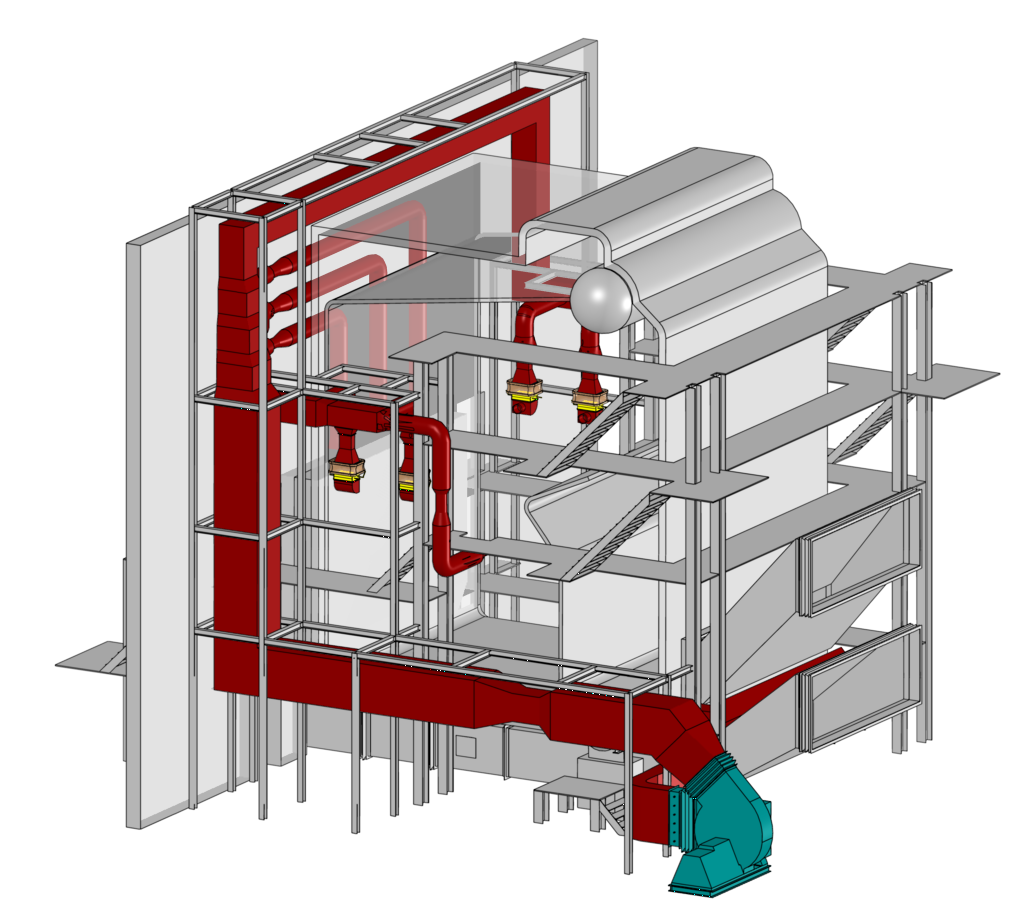

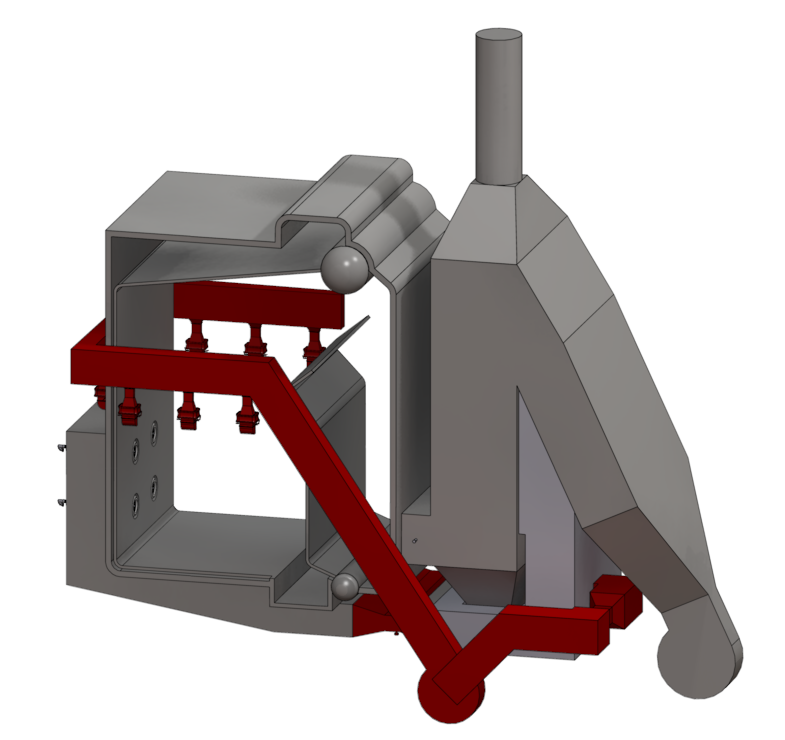

Briefly explained, the STORM® fan-boosted OFA system is pre-heated combustion air supplied from the wind-box or secondary air ducts, metered and fan boosted to nozzles strategically located throughout the boiler. This setup provides accurate and reliable measurement to each nozzle for proper combustion and NOx tuning during unit operation. Measurement devices (venturi sections) enable a total

OFA airflow measurement as well as a measurement to each individual nozzle.

The different configurations will allow for improved complete mixing prior to the furnace exit. The above sketch denotes a couple of scenarios for achieving optimum conditions. Each unit has its own characteristics and should be tuned based on testing furnace exit gas & temperature profiles and in-situ flyash carbon content samples at the air-heater outlet.

The concept of the fan boosted over-fire air system is extremely effective and will provide significant results. STORM® stakes a comprehensive approach to optimization and recommends other unit improvements to compliment this system. These improvements mostly deal with the unit inputs, fuel, and air. The majority of combustion improvements deal with airflow management, pulverized, and burner improvements. The advantages of the fan boosted over-fire air fan system versus no or non-boosted OFA system are summarized as follows:

- Most Economical System for the Greatest NOx Reduction

- Approximately 90% of the Components Can be Installed with the Unit On-Line.

- Existing OFA Systems Can be Easily Modified to a Fan Boosted OFA System

- More Complete and Intense Mixing Prior to Furnace Exit to Reduce Stratifications of Temperature, Oxygen, CO, and NOx constituents

- Lower Furnace Exit Gas Temperatures

- 40% – 60% NOx Reduction(Depending on system configuration)

- Allow for More Complete Combustion and Reduction of Unburned Carbon(LOI)

- Reduction of Spray-Flows and Slagging in the Convection Pass

- Improved Unit Efficiency, and Reliability Reducing Forced Outages