Lab Services

STORM provides a complete package of lab testing analysis for weekly or monthly monitoring in-house. By providing regular monitoring services, results are achieved in the performance and reliability of the boiler.

-

Next Day Results for Fuel Fineness and LOI’s

-

Detailed Summary of Results Including Recommendations to Improve Results

-

Discounted Rates Based off of Quantity of Samples

STORM offers complete lab services of flyash and coal fineness analysis and determines the areas of improvement.

- Flyash Unburned Carbon Analysis

- Flyash Sieve/LOI 3-Part Analysis

- Coal Fineness Analysis

STORM can provide a complete package of testing analysis for weekly or monthly monitoring. By providing regular monitoring services, results are achieved in the performance and reliability of the boiler.

Benefits:

- Weekly/Monthly Monitor and Reporting Lab Service

- Access to History Records Online

- Engineering Staff Available to Answer Question

- Timely and Fast Turn Around (Often 24 Hours after Samples Arrive)

- We Provide Pickup Service for Local Plants within 100 miles

- Affordable Price

- Weekly/Monitoring Lab Services available

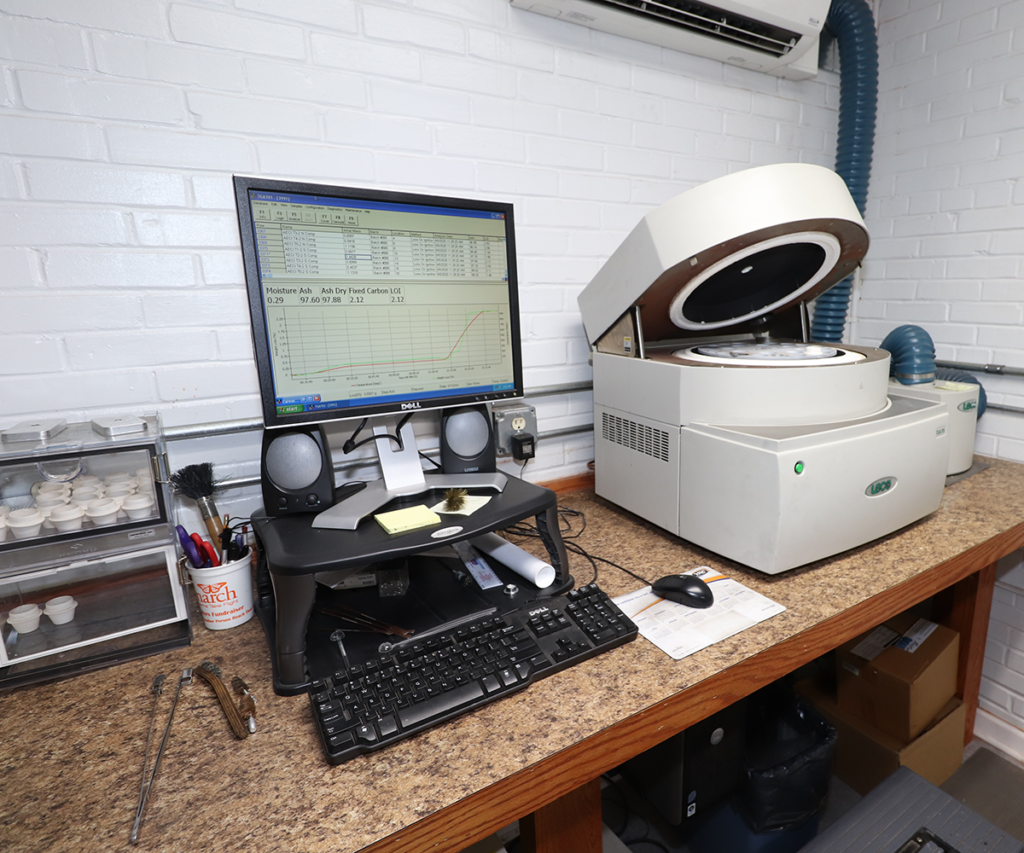

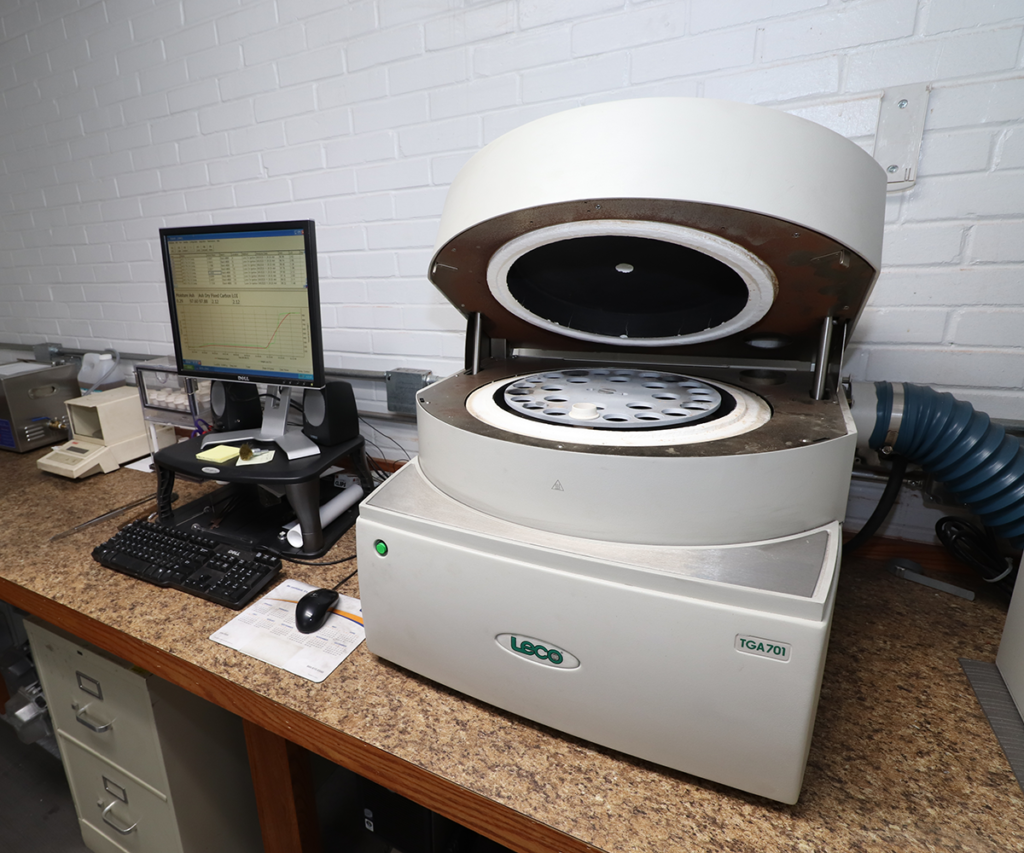

STORM utilizes TGA701 Thermogravimetric Analyzer to determine the composition of the flyash sample collected. The instrument consists of a computer and a furnace that allows multiple samples to be analyzed simultaneously. Utilizing LECO’s TGA 701 Thermogravimetric Analyzer, Storm Technologies performs flyash analysis and weekly or monthly monitoring services to evaluate combustion performance. Please contact us for more information on which monitoring plan best suits your company.

Flyash Unburned Carbon

The amount of carbon left unburned can be monitored on a regular basis. A STORM designed Insitu Flyash Sampler such as the one shown provides the means to draw extremely representative ash samples from the flue gas for analysis.

3 Part Flyash Sieve/LOI

Monitoring composite ash samples, +200 mesh and -200 mesh unburned carbon in flyash, serves as a tremendous tool for monitoring weekly and/or monthly combustion performance. This type of analysis is not something most utilities are familiar with but by sieving the flyash and analyzing the fine, coarse and composite samples more insight can be gained on the factors that are causing your LOI’s to be higher than desired. Regular monitoring is a big advantage in knowing how the boiler is performing when it comes to combustion optimization. Give us a call today and see how our lab service can be a benefit to your organization.

Coal Fineness Analysis

Maintaining coal fineness levels that meet or exceed 75% passing a 200-mesh sieve and less than 0.1% retained on a 50-mesh sieve is an important essential to help ensure optimum combustion can be achieve in a coal fired boiler with a low NOX firing system. STORM’s coal fineness service will provide your facility with sieve results from each individual pipe as well as an overall weighted averaged (if isokinetic sampling) is completed. These results will be plotted on a Ros-Rammler plot to ensure the results are accurate. By monitoring the fineness of your pulverizers on a quarterly basis, you can develop a performance-based maintenance plan for you pulverizers that is not solely based off throughput or operating hours. Furthermore, frequent fineness testing can also help identify problems when they begin and before they cause an unexpected forced outage or also the need to classifier tuning to maintain your fineness levels between scheduled overhauls/outages.