Pulverizer Optimization Components

The pulverizer is the heart of the plant, and we want to make sure it is operating to the best of its capacity.

Is the heart of your plant running at its finest?

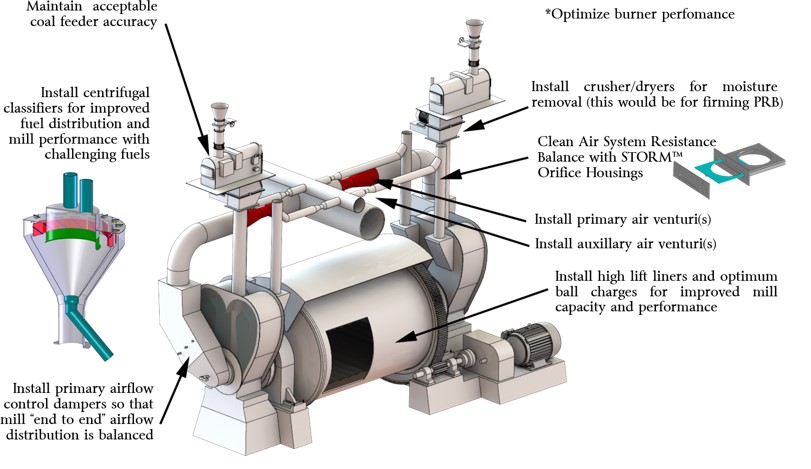

Often, we visit plants that perform pulverizer maintenance based on operating hours, or fuel tons throughput. In our view, pulverizer maintenance should be driven by periodic tests of pulverizer performance. The important elements of pulverizer performance are fineness, fuel distribution, coal (pyrites) rejects, and primary airflow calibrations. Optimizing pulverizer performance is a prerequisite for optimum furnace combustion. About three-fourths of the 13 Essentials are pulverizer, primary air, and fuel line related. The pulverizers are truly the heart of a modern pulverized coal-fueled boiler.

STORM® has its own fabrication shop that allows us to provide fast, reliable, and quality work for each job opportunity. Over the past years, numerous venturis, classifier blades, rotating throats, as well as complete centrifugal classifiers have been completed and installed on a variety of pulverizers.

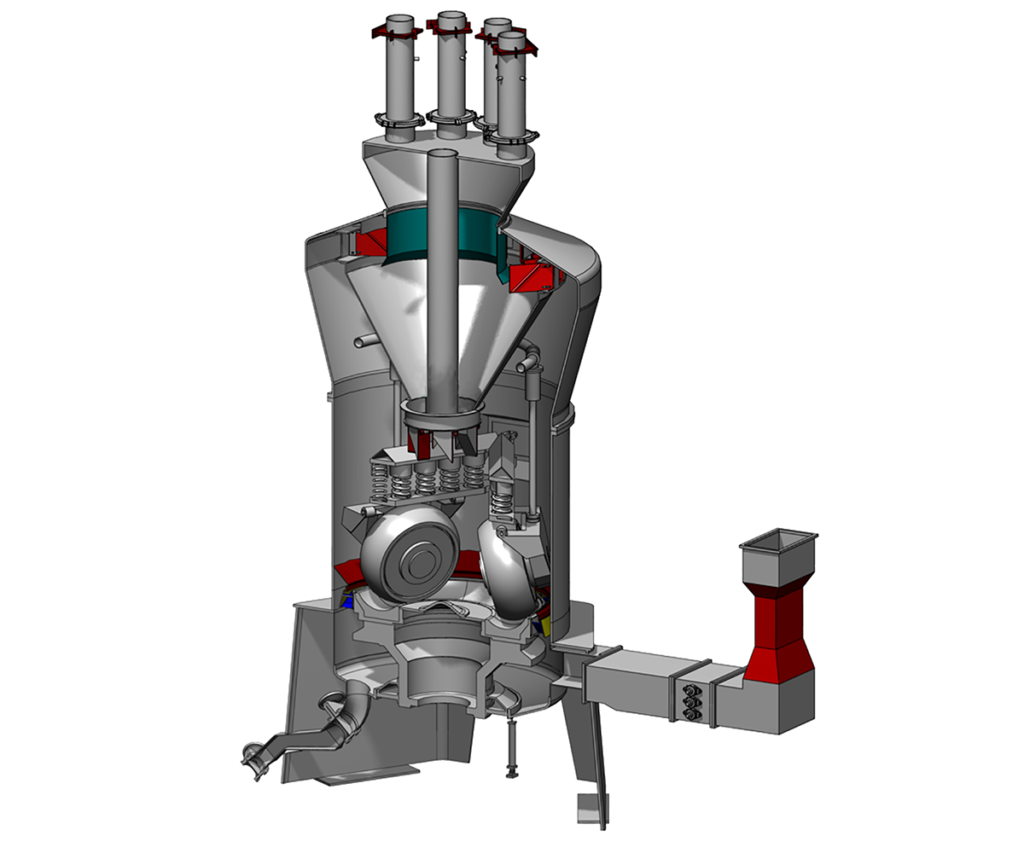

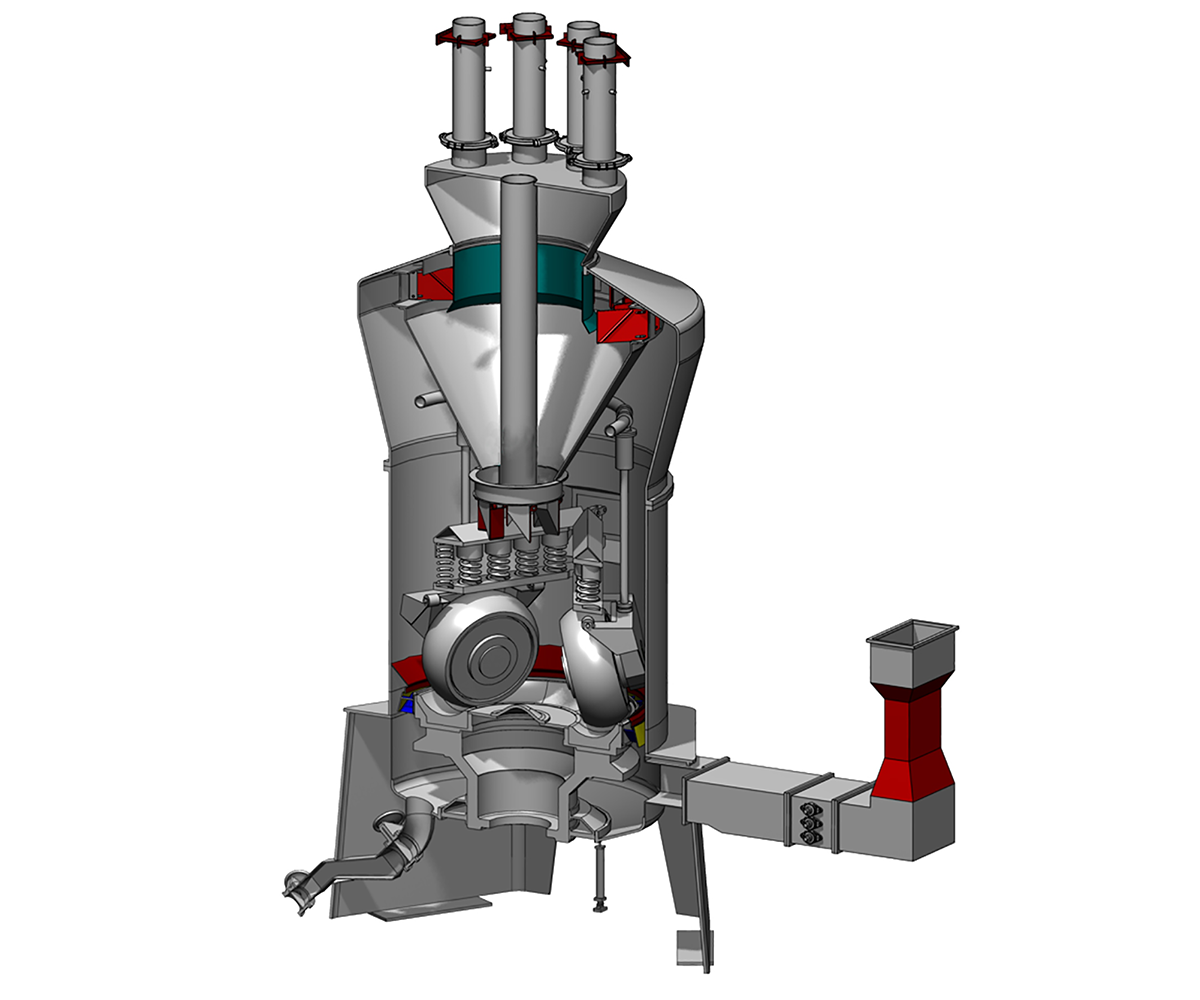

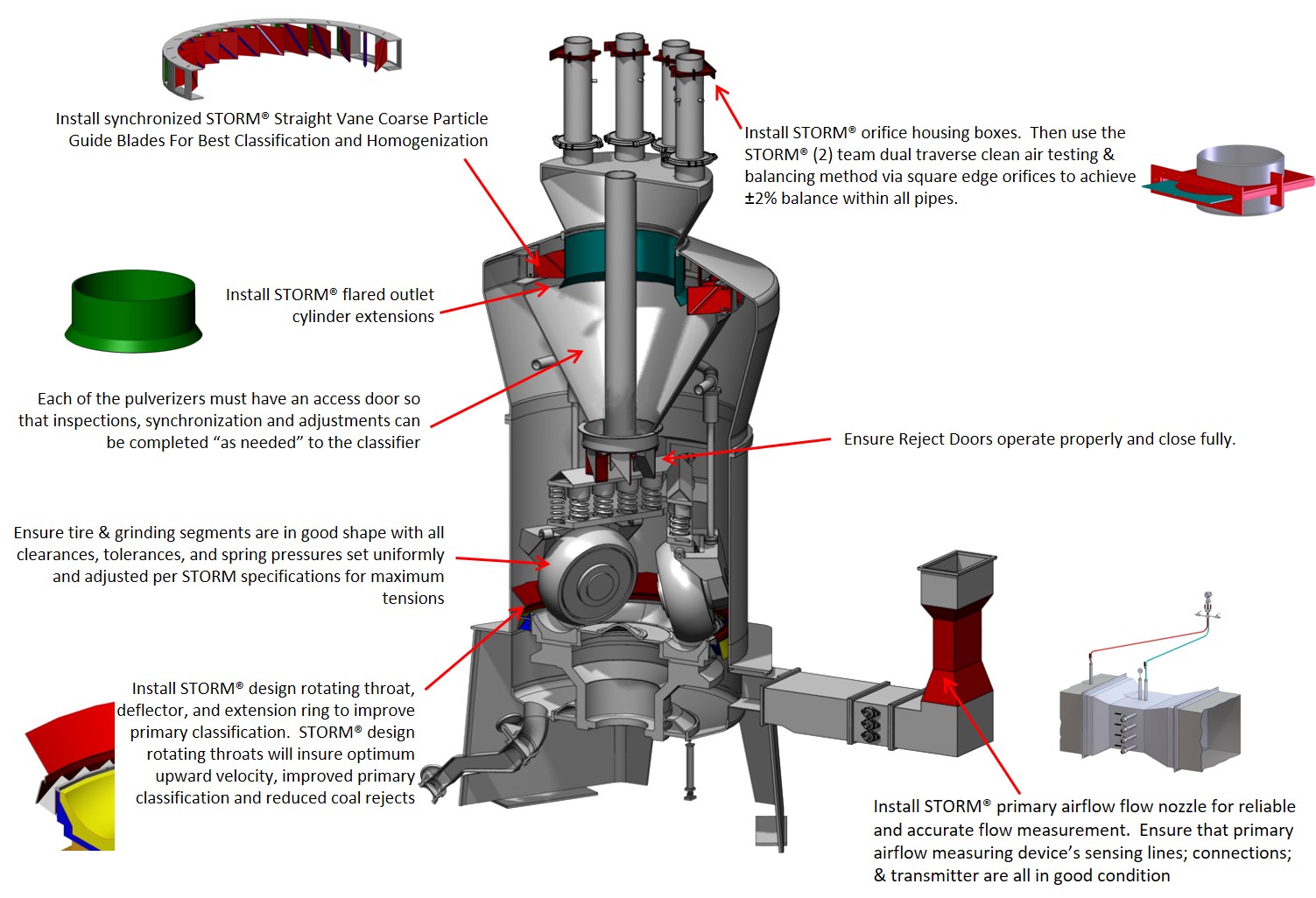

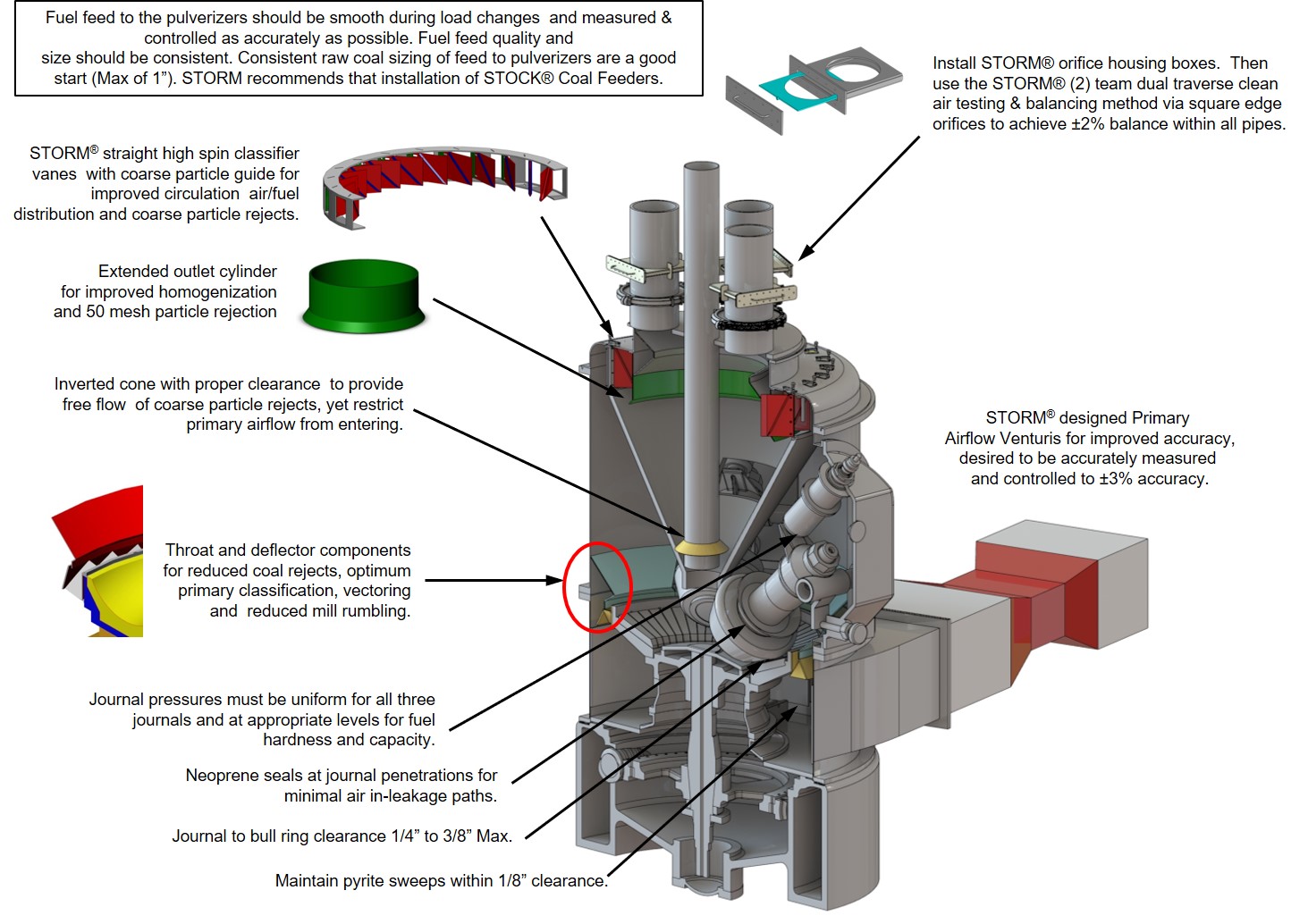

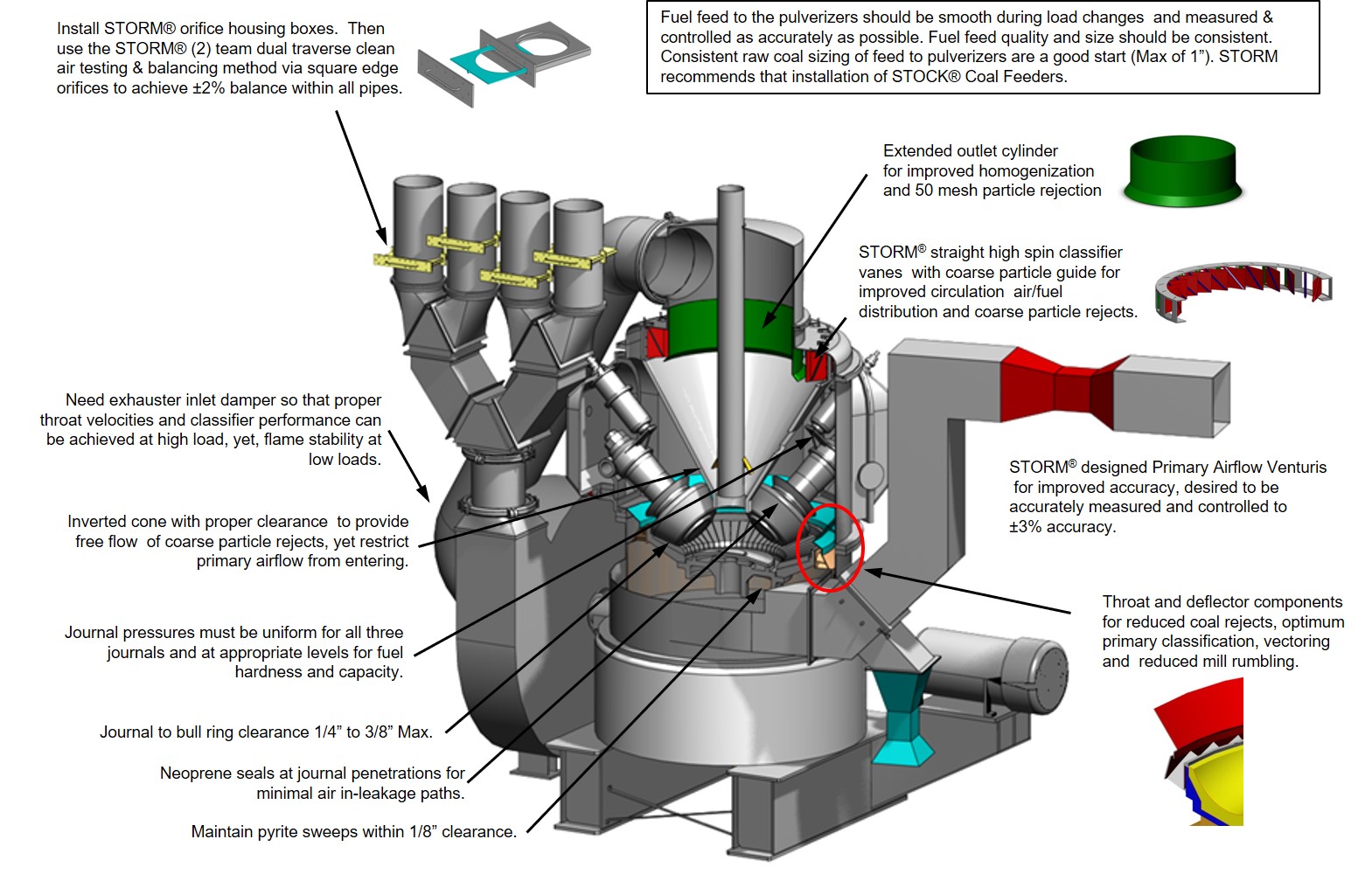

When it comes to pulverizers, we focus on the following components:

- Airflow Measurement and Management Systems

- Rotating Throats and Deflectors

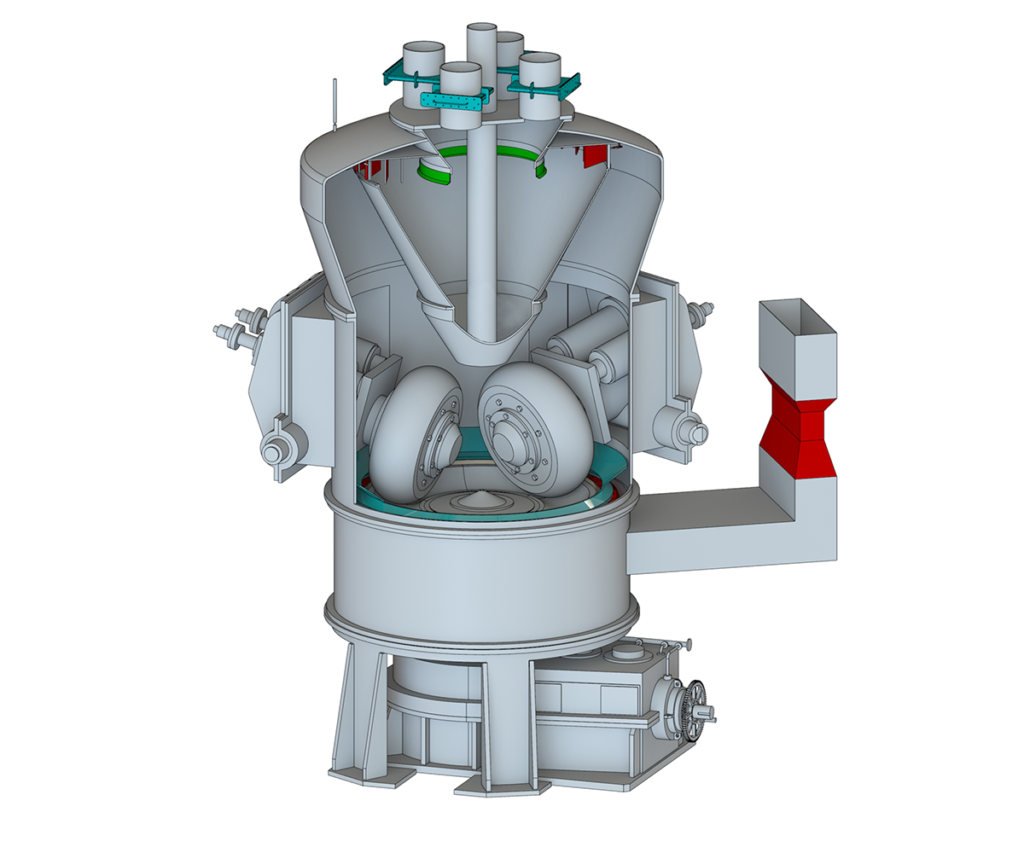

- High Spin Classifier Vanes

- Modified Outlet Cylinder Extension

- Classifier Reject Doors

- Fuel Line Orifices Housings

At the bottom of this page are STORM’s typical recommendations for the variety of pulverizers we service.

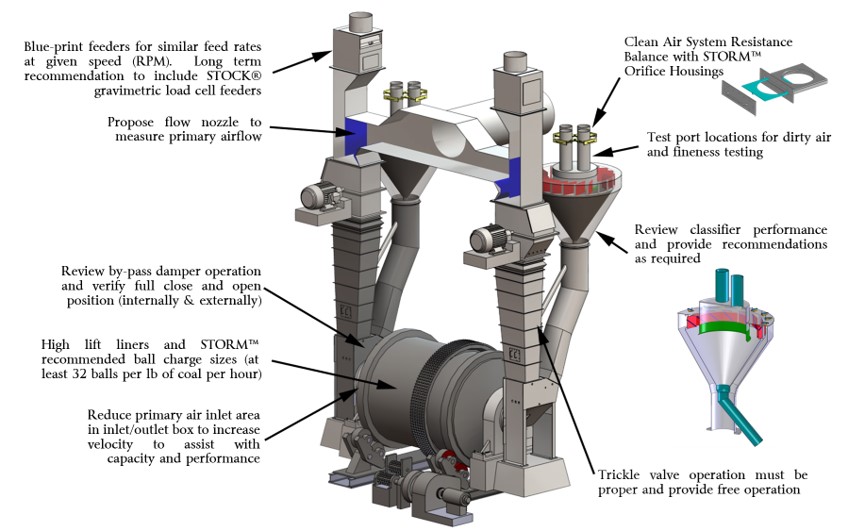

STORM® has vast experience in the design, fabrication, and calibration of many different types of airflow measurement devices. We frequently find that plants are unaware of poor primary airflow management and control. An essential first step to good air management is the metering and proper distribution of the air. Depending on the location in the ductwork, venturis or flow nozzles are preferred. The benefits of venturis include:

- Improved unit and pulverizer controllability by improving the “K” factor accuracy and repeatability

- Smoother differential signal

- Capability to improve DCS logic and control curves so that an optimum airflow can be achieved across the normal operating load range

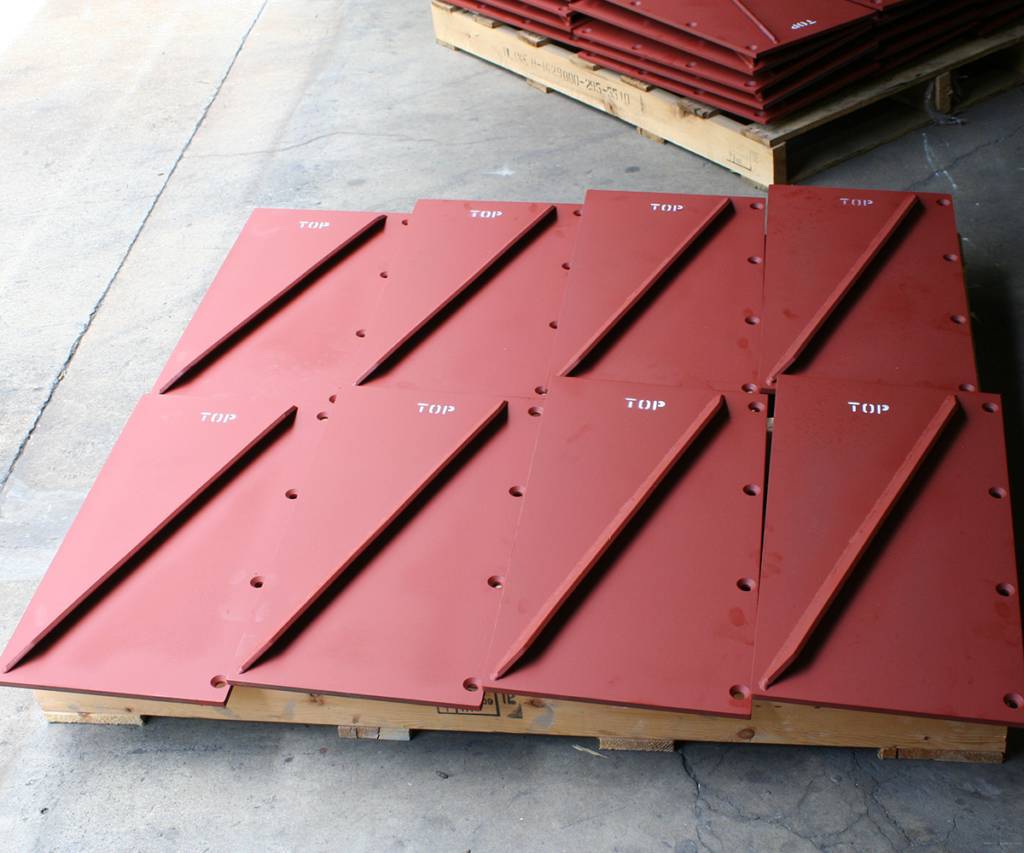

STORM Rotating Throat and Deflector

An optimum pulverizer throat configuration is a big deal. The pulverizer throat area and configuration must be right to minimize coal rejects at the optimum air/fuel ratio; must help turn down to a minimum load without “rumble”; and must be configured to not have quiescent zones that contribute to mill fires. The throat areas must be compatible with the fuel lines and burner nozzle areas so that optimum velocities.

Observable characteristics of good pulverizer performance include minimum coal rejects and no rumbling/skidding. Minimum coal rejects means that your primary airflow, grinding zone, and throat areas are compatible and are operating correctly. Maintaining this level of performance is important since too many rejects can pose a fire risk. Rumbling or skidding may not pose a direct performance penalty, but it can affect the long term reliability of the pulverizer components. Lower maintenance costs are an indirect result of optimum pulverizer performance.

Benefits include:

- Reduced or eliminated coal rejects, improved vectoring for improved grinding, and improved primary airflow controllability.

- Increased pulverizer & furnace residence time.

- Improved coal fineness.

- Capability to reduce air/fuel ratios.

- Reduced FEGT’s with improved combustion lower in the furnace.

- Reduced available “free” oxygen in the high temperature flame core.

- Excessive amounts of primary airflow tend to force ignition points away from the burner as a result of higher burner nozzle velocities, thus allowing infusion of oxygen “rich” air into the flame core and increasing NOx exponentially.

- Reduce pulverizer vibration & rumbling.

- The deflector sets an open area to maintain an acceptable velocity to keep coal particles in suspension and prevent coal spillage.

Classifier Components

If the overall combustion performance, including NOX, fineness, fuel distribution, LOI, and superheater slagging cannot be improved with pulverizer grinding elements, then consideration should be given to the installation of new or upgraded STORM® static-centrifugal classifier modifications. Classifiers should provide the appropriate capability to achieve fineness and also as a classifier, but also homogenize the fuel distribution from pipe to pipe. This mixing function is equally important as coarse particles return to the pulverizer.

STORM® designed static classifiers and modifications have been field-proven on all types of pulverizer systems. In many plants, they offer the most technically feasible solution, compatible with burner and other reduced NOx changes.

Benefits include:

- Reduce 50 Mesh (Coarse Particles) By-Pass

- Reduce the intensity of “Oxidizing” and “Reducing” Atmospheres with Furnace

- Reduction of Carbon In Ash (LOI)

- Improved Swirl, Fuel Homogenization and Fuels Distribution (Must be Properly Designed and Primary Airflow Measured and Controlled)

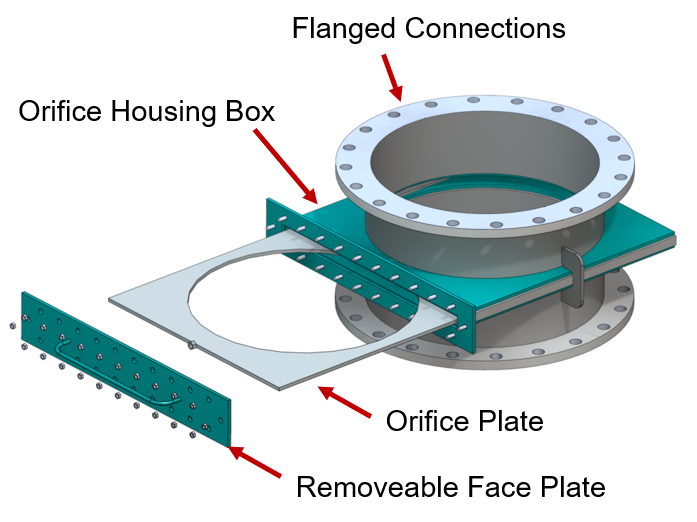

Fuel line balancing via square edge orifices is the first step in balancing fuel to individual burners. Air is the medium that carries fuel to the burners. Properly balanced fuel lines, by clean air balancing, benefits burner performance, fuel distribution, combustion, boiler efficiency, and NOx reduction.

Balancing system resistance of fuel lines by the clean air method is the first phase of a comprehensive fuel and air balancing program. It is important to remember that a clean air balancing program is an important factor in optimizing pulverizer fuel and air balance and we have made it easier.

The STORM® designed orifice housing allows quick and easy installation changes for square edge orifices. The orifice plate easily slides in and out of the housing, making orifice changes very simple and safe.

Benefits include:

- Easy Installation for Balancing Fuel Lines to ±2% (Clean Air)

- Improved Combustion (reduced FEGT/LOI, etc.)

- Improved Boiler Efficiency

- Improved Burner Performance

- Reduced Slagging and Fouling

- Allow for Improved Fuel Flexibilities

- Improved Fuel Distribution

- NOx Reduction

- Use as Isolation Point in Fuel Line

Typical STORM Optimization Recommendations for Pulverizers

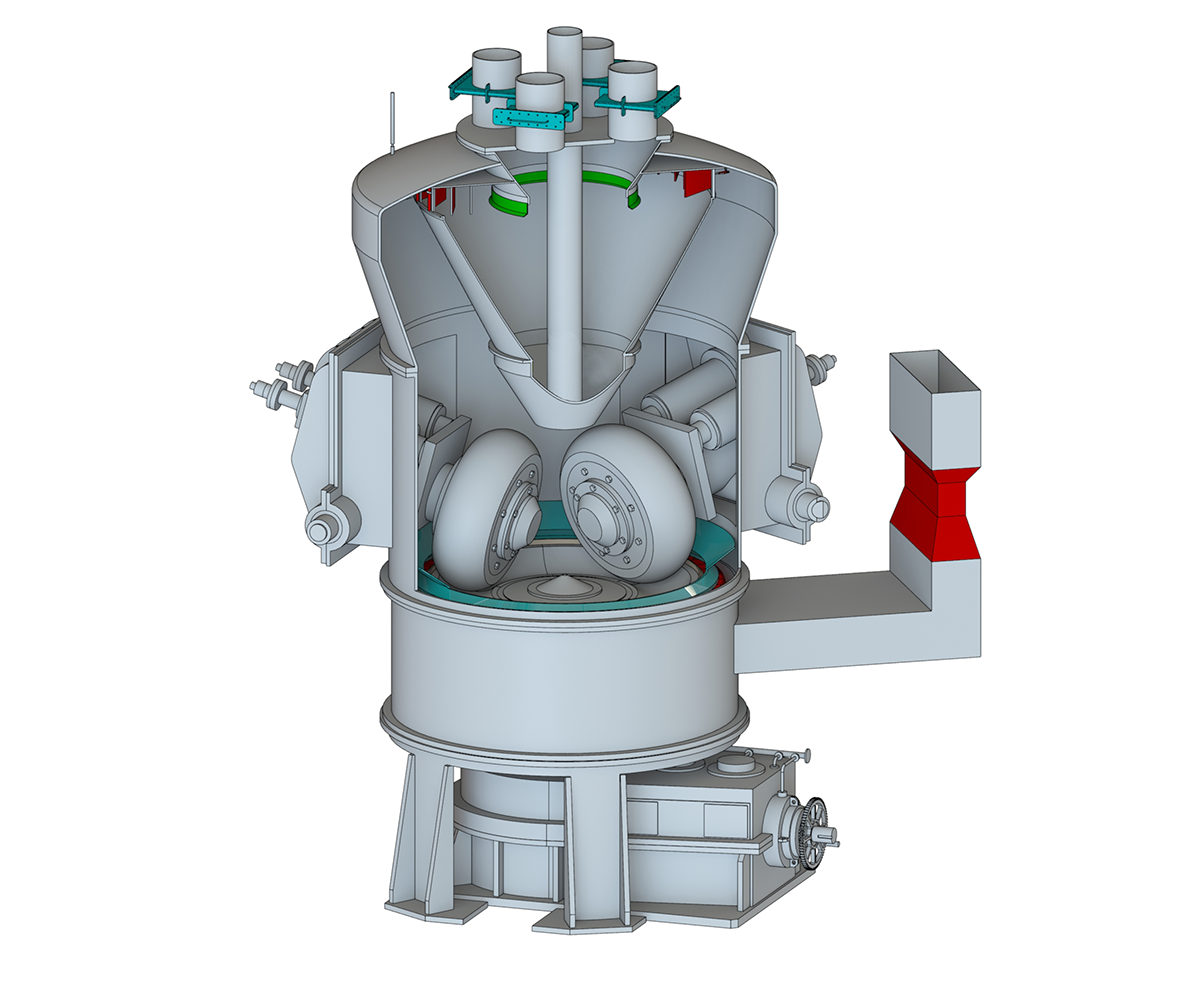

MPS Pulverizer

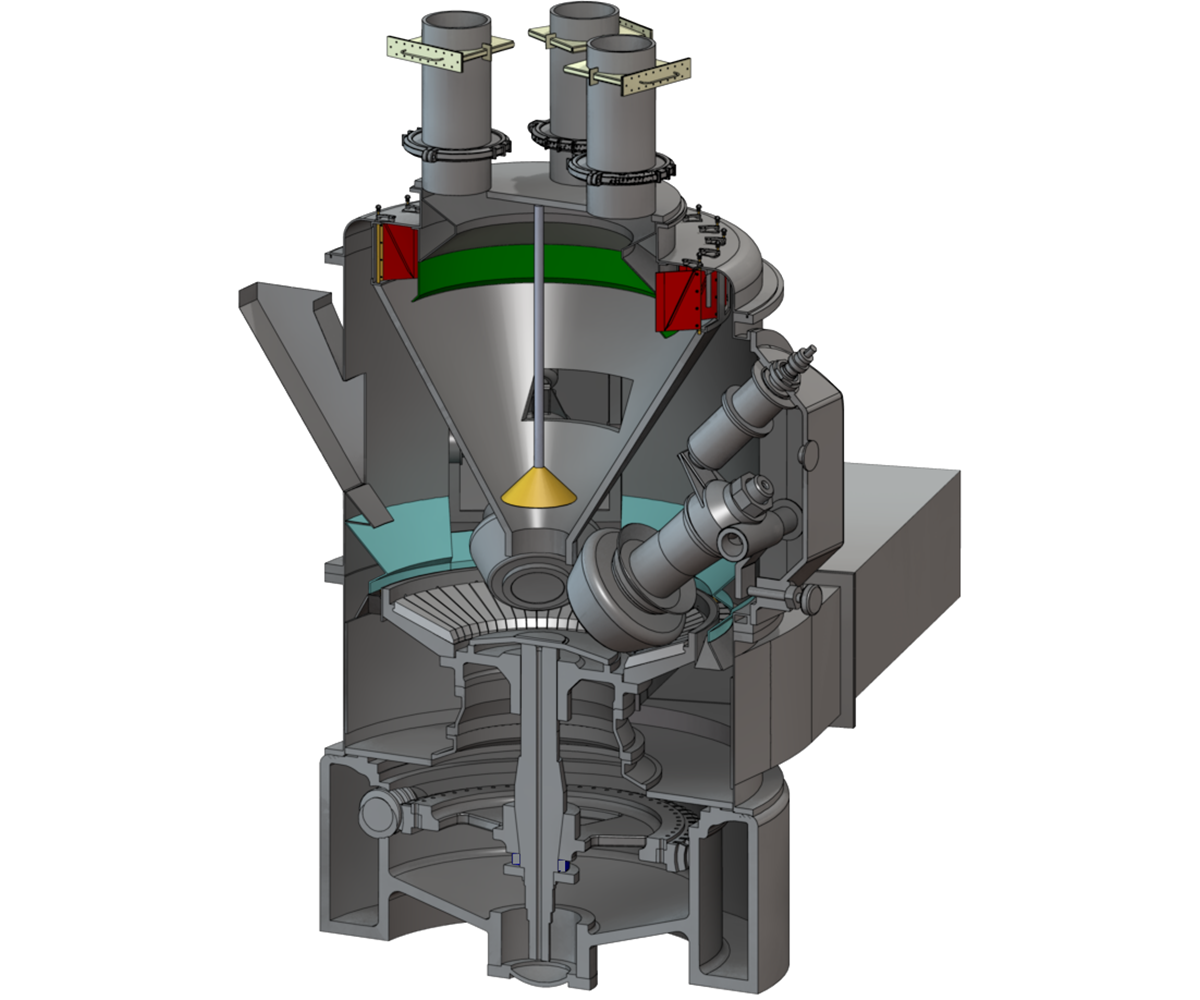

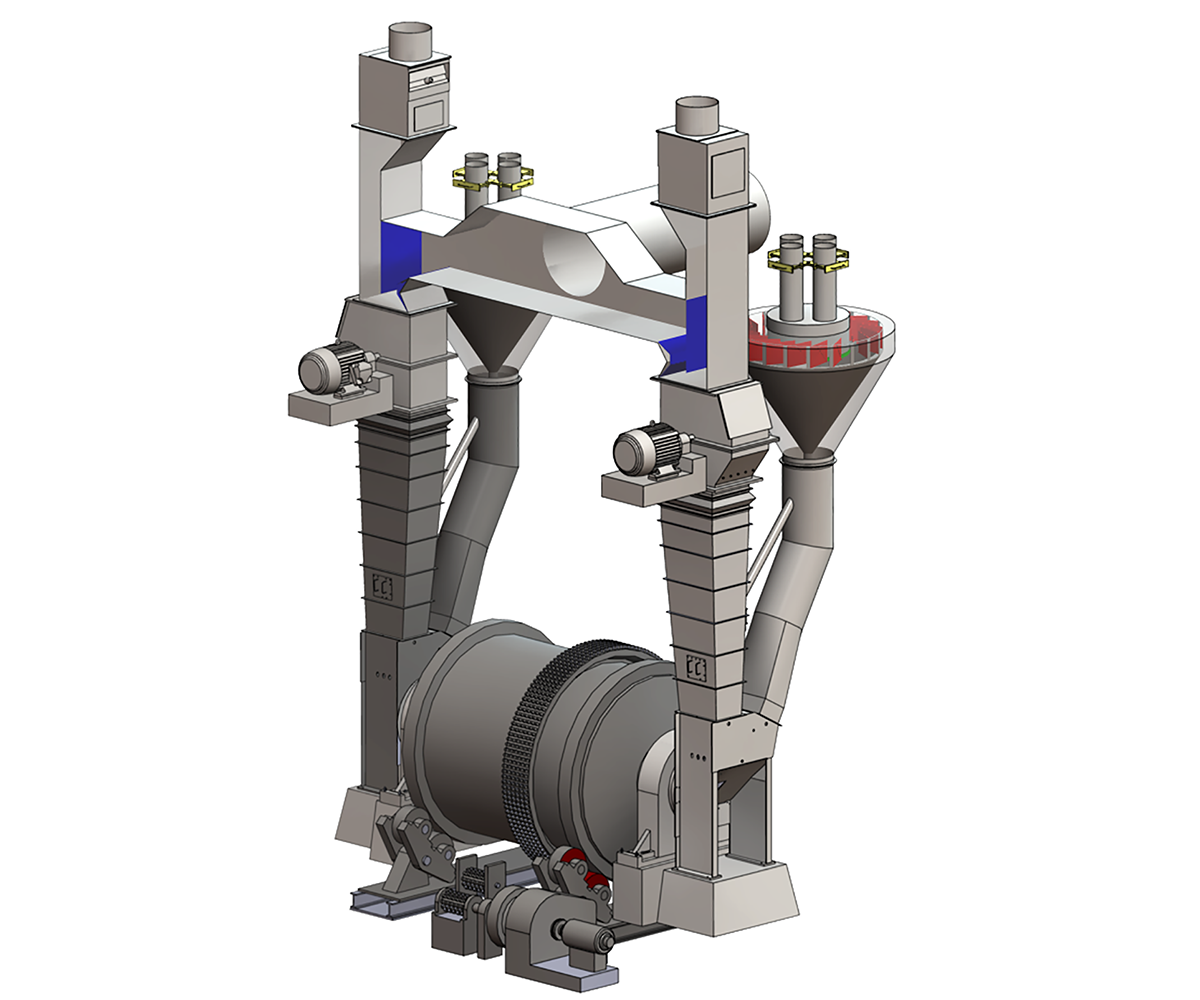

MBF Pulverizer

Raymond Pressurized (RP) Bowl

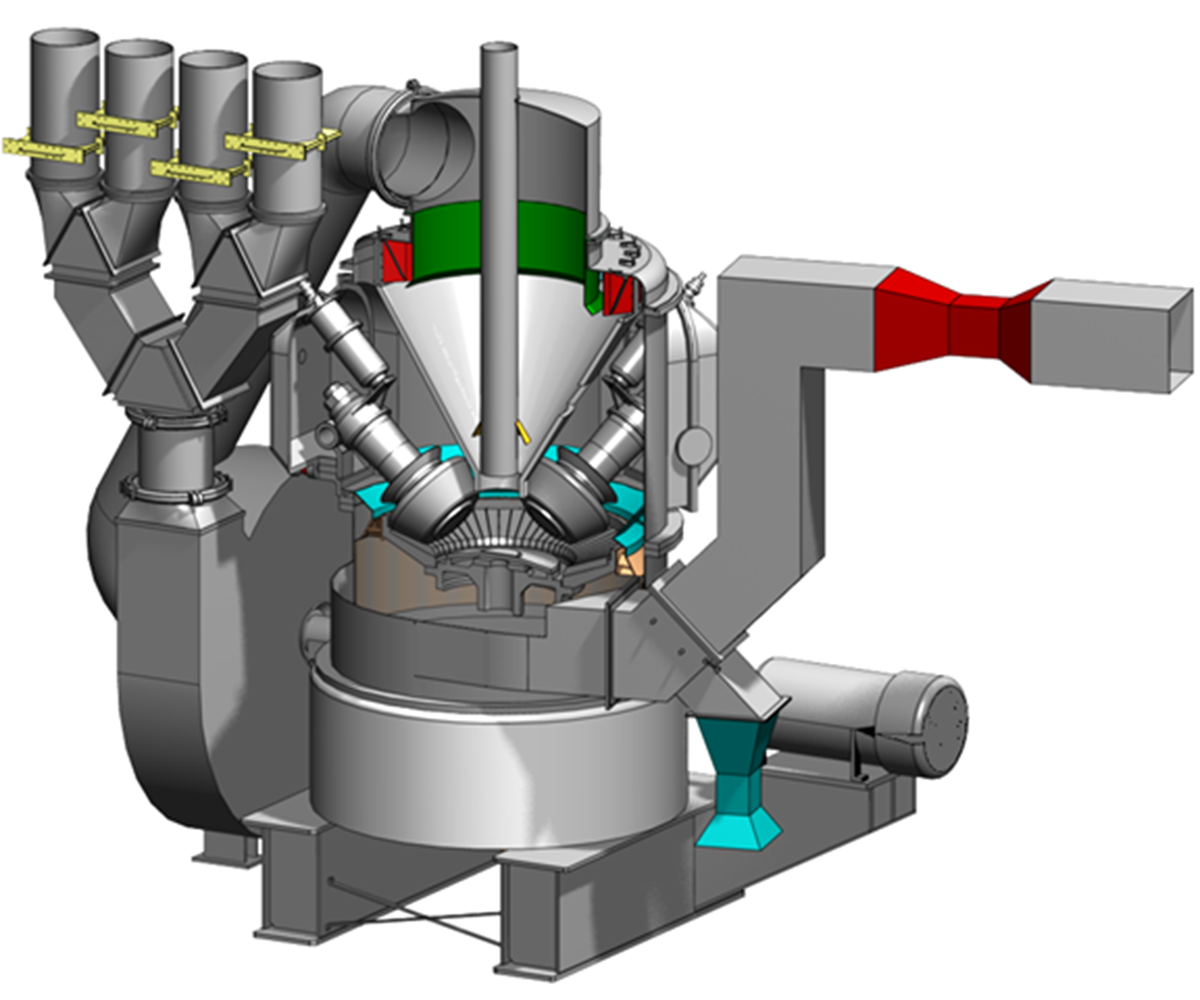

Raymond Suction (RS) Bowl

Foster Wheeler Ball Tube Mill