STORM Impluse Cleaner

Are you in search of an alternative cost-effective cleaner for your boiler?

-

Provides effective cleaning without erosion or damage to the heat transfer surfaces

-

No costly repair, maintenance or operational costs.

-

Shockwaves are encompassing and penetrate deeper into the tube bundle than traditional sootblower “line of sight” cleaning

-

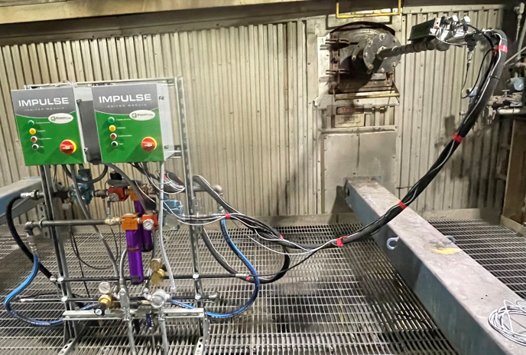

Minimal intrusion into and out of boiler, has minimal installation footprint and minimal installation costs.

-

Orders of magnitude more powerful and effective than traditional acoustic cleaning systems

-

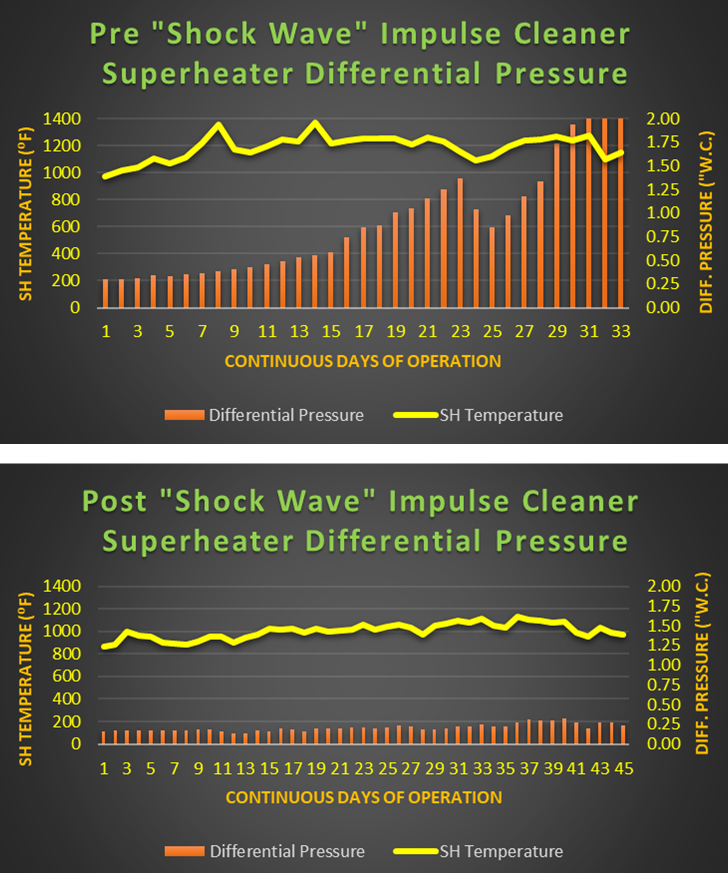

Can improve heat transfer efficiency, reduce operational and maintenance costs, and minimize or eliminate costly unplanned outages

The STORM Impulse Cleaning system enhances boiler operation and minimizes high maintenance expenses associated with other cleaning methods. This revolutionary technology provides significant advantages over traditional boiler cleaning methods like sootblowing, rapping, manual shaking, blasting, and high-pressure water washing.

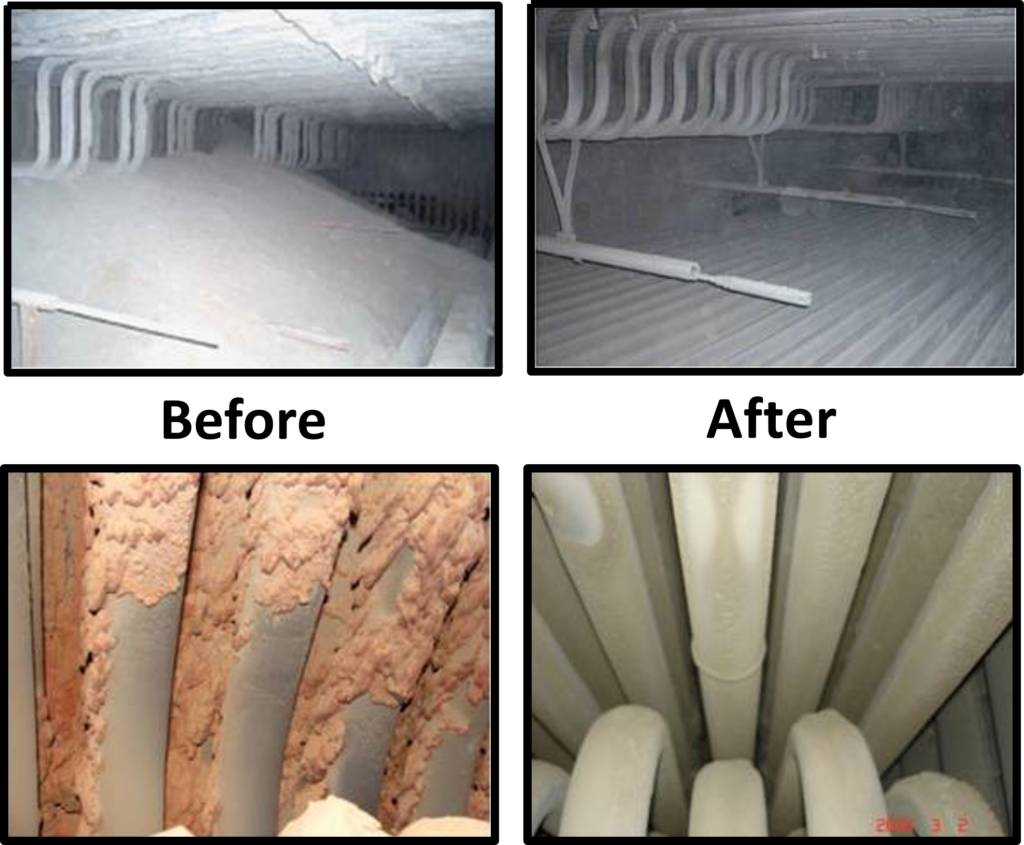

The cleaning technology operates online and uses controlled and repeated pressure waves to dislodge buildup from heat transfer surfaces proactively. While powerful, the cleaning technology will not damage or erode heat transfer surfaces. It’s also virtually maintenance-free.

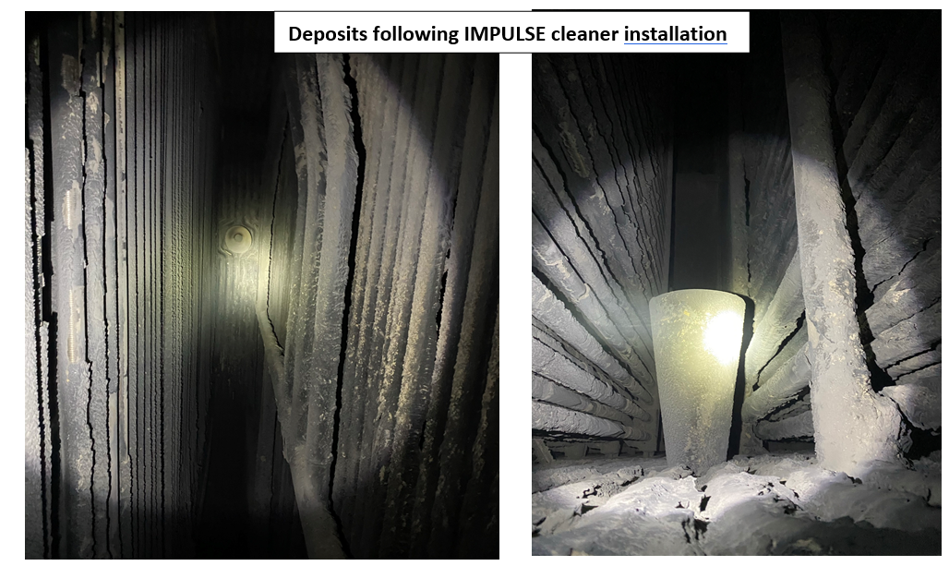

Buildup, fouling, and slagging of heat transfer surfaces can cause tubes to become insulated with particulate. This diminishes convective heat transfer, reducing efficiency and requiring more fuel to maintain steam output. The powerful cleaning technology augments, or could potentially replace, current cleaning systems used to dislodge buildup and deposits on convection surfaces in boilers and heat exchangers.

This approach provides a high penetration level, and can dramatically increase performance compared to alternative methods like sootblowing, with reduced operating costs and minimized tube and shield damage.

System Specifications:

| Electrical: | 110/220 VAC |

| Fuel: | Ethylene Gas (C2H4) |

| Fuel Consumption: | Based on operation |

| Impulse/Cycle: | 20 bursts (typical) |

| Cycle Frequency: | Every 30 min. to 1 hour |

| Oxidizer: | Plant air |

| Air Consumption: | 100-120 SCFM @ 70-90 PSI |

| Material: | Stainless steel |

The STORM Impulse Cleaner is constructed from 3 separate pieces that are bolted together in the field.

The “A”-section, also referred to as the combustion chamber, is fabricated from stainless steel and is about 48” long and 2″ in diameter.

The “B”-section is a casting that diverges from 2″ out to approximately 6″ in diameter over an axial length of 30″. There are 2 options: a straight or curved version. The curved section has a 90-degree bend in it, which allows for a slim mounting profile.

The “C”-section diverges from 6” out to 9-16” over the length and is typically partially located inside the boiler.