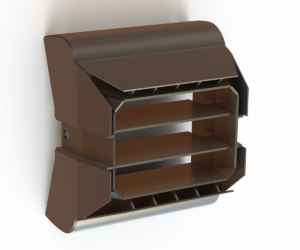

Fabrication Capabilities

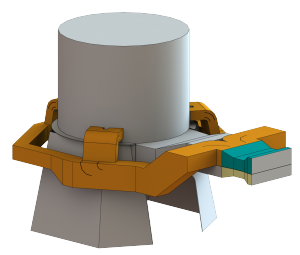

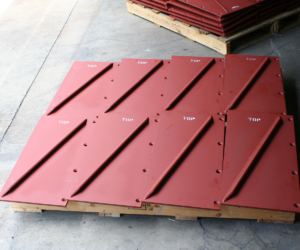

STORM manufactures much of its engineered solutions and optimization components it recommends to our customers. Working with Fabricated Solutions, a division of Storm Technologies, we can expedite fabrication while maintaining high quality to meet our customer’s needs and schedules.

-

Up to same-day turnaround on quotations and proposals

-

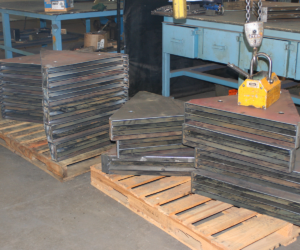

20,000+ sqft ASME code fabrication facility

-

Capability to start same-day on expedited projects

Fabricated Solutions, a division of Storm Technologies, Inc., is a fully capable, experienced, and skilled engineering, design, and fabrication facility in which almost all your fabrication needs may be met.

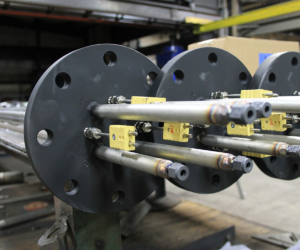

We have a variety of shop equipment to help meet your manufacturing needs. Our facility is capable of plasma cutting, milling, sawing, forming, breaking, rolling, shearing, drilling, tapping, cutting, welding, and grinding most types of steel.

Our engineering and quality control department ensures that all products are completed correctly the first time and are completed when our customers need them. Fabricated Solutions is the core producer of all STORM® designed components.

ASME Code Welding

Fabricated Solutions carries three certifications in compliance with the American Society of Mechanical Engineers (ASME) and National Board code for work on pressurized vessels.

ASME “S” Stamp for the manufacture and assembly of power boilers under Section I of the latest copy of the ASME Boiler and Pressure Vessel Code.

ASME “U” Stamp for the manufacturing and assembly of Unfired Pressure Vessels per ASME Section VIII Division I.

National Board of Boiler & Pressure Vessel Inspectors Certified “R” Stamp for the repairing and alteration of Power Boilers, Pressure Vessels, and other pressure-retaining items.